Torsional rigidity refers to a material's ability to resist twisting or torsional forces. In the context of PVC inflatable boat fabric, strong torsional rigidity is a critical principle that contributes to the boat's stability, handling, and overall performance on the water. Here's how the principle of strong torsional rigidity is achieved and its significance for inflatable boats:

1. Material Properties: The choice of PVC fabric contributes significantly to the torsional rigidity of inflatable boats. PVC fabric used in boat construction is engineered to have specific properties that enable it to resist twisting forces and maintain its shape.

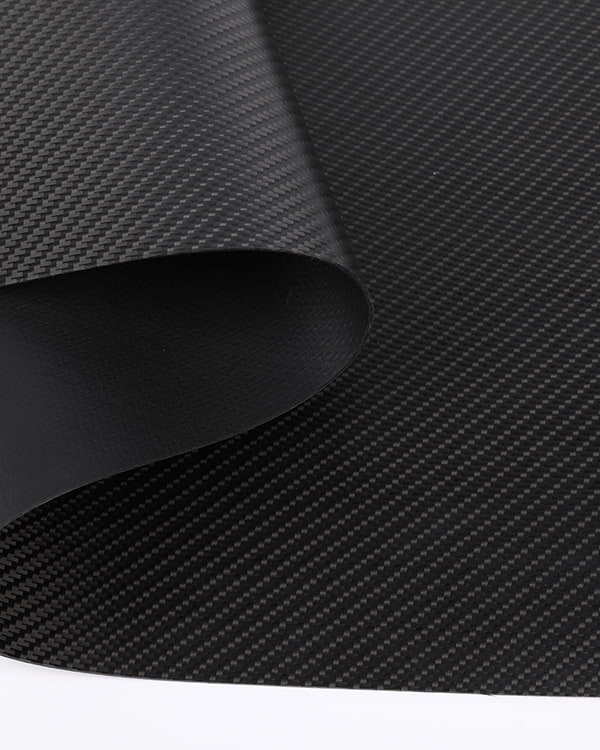

2. Fabric Weave and Layering: The construction of PVC fabric involves multiple layers of materials, often with reinforcing elements like polyester or nylon fibers. The arrangement and weaving of these layers contribute to the fabric's resistance to torsion.

3. High-Frequency Welding or Heat Sealing: The seams and joints of inflatable boats are typically constructed using high-frequency welding or heat-sealing techniques. These methods create strong and continuous bonds between fabric panels, enhancing torsional rigidity by preventing the panels from separating or twisting relative to each other.

4. Structural Design: The overall design of the boat, including the arrangement of chambers and compartments, contributes to torsional rigidity. Strategic placement of air chambers and reinforcements helps distribute torsional forces evenly across the boat's structure.

5. Keel and Floor Design: The design of the boat's keel and floor contributes significantly to torsional rigidity. Reinforcements along the keel and a well-designed floor help resist twisting forces and maintain the boat's intended shape.

6. Stiffening Elements: Some inflatable boats may include additional stiffening elements, such as rigid floorboards, aluminum or fiberglass panels, or inflatable keels. These elements further enhance torsional rigidity and contribute to the boat's stability and handling.

7. Inflation Pressure: Proper inflation of the boat's air chambers is crucial for achieving strong torsional rigidity. Adequate air pressure ensures that the fabric panels are stretched taut and resist twisting forces effectively.

Significance of Strong Torsional Rigidity for PVC Inflatable Boats:

1. Stability: Strong torsional rigidity ensures that the boat maintains its intended shape and doesn't twist or deform excessively when subjected to external forces. This stability is essential for safe and controlled navigation.

2. Handling and Maneuverability: Torsional rigidity contributes to the boat's responsiveness to steering and maneuvering inputs. It allows the boat to respond predictably to the operator's actions, enhancing overall control and handling.

3. Performance in Waves and Currents: A boat with strong torsional rigidity performs better in challenging water conditions, such as waves or currents. It maintains stability and control, reducing the risk of capsizing or loss of control.

4. Safety: Torsional rigidity is a safety feature, as it prevents the boat from twisting or flexing excessively during use, reducing the likelihood of accidents or instability.

English

English 中文简体

中文简体 русский

русский

浙公网安备33048102240301

浙公网安备33048102240301